Ultra dense PVD coating with optimal thermal resistance & added strength for general purpose.

YG602

|

|

Universal grade for General Milling Application

|

YG622

|

|

Optimized Grade for High Alloyed or Prehardened Steel Excellent hot hardness and oxidation resistance at high speed |

YG712

|

|

Universal grade for General Milling Application |

YG603

|

|

Tough Milling grade for Stainless Steel

|

YG501

|

|

Hard Milling grade for Cast Iron

|

YG5020

|

|

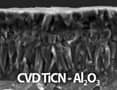

CVD Milling grade for Cast Iron

|

YG50

|

|

Uncoated Milling Grade for Aluminium

|

Milling Chipbreakers

| –AL |  |

|

| –ST |  |

|

| General Inserts (No Description) |  |

|

| –TR |  |

|

| ...W / ...N |  |

|