Introducing our high-quality steel roofing sheets, designed to provide exceptional durability and reliability for all your roofing needs. Made from premium-grade steel, these sheets offer outstanding strength and resistance to harsh weather conditions, ensuring long-lasting protection for your property.

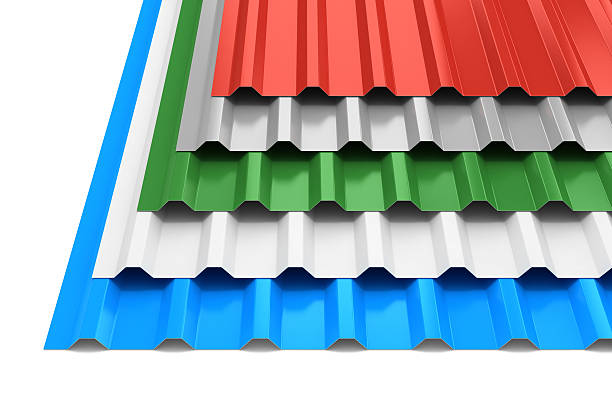

Our steel roofing sheets are available in a range of sizes, thicknesses, and profiles, allowing you to choose the perfect fit for your project. With a variety of finishes available, including galvanized, color-coated, and plain, you can customize your roofing to suit your aesthetic preferences.

Our steel roofing sheets are lightweight and easy to install, reducing labor and installation costs. They also require minimal maintenance, making them a cost-effective choice for commercial, industrial, and residential buildings.

Our roofing sheets are manufactured to the highest standards and are backed by a comprehensive warranty, giving you peace of mind that your investment is protected. Whether you are constructing a new building or replacing an existing roof, our steel roofing sheets are the ideal choice for superior performance and lasting durability.

Invest in our steel roofing sheets today and enjoy the benefits of a reliable, long-lasting roofing solution that will keep your property safe and secure for years to come.

HIGHLIGHT FEATURE OF THE BRAND INCLUDES:

- High precision process and equipment reliabilty.

- High productivity and quality control is our moto.

- Precise tube diameter, high surface quality and optimum tube straightness is our USP.

Tested raw material from prime manufacturers such us JINDAL, TATA, SAIL,

Apart from this extensive range, the company also has the following ongoing projects that increase the products and services being offered:

Cut to Lenth Imm to 10mm strip thickness x width 1500mm

12″ Pipes HR Tube Mill are currently in high demand to be used in infrastructure projects.

QUALITY CONTROL:

During production, online visual inspection is also carried out for surface defects, diameter accuracy, quality and weld bead shape. Required sample rings as per specification are cut to carry out mechanical testing of weld and body e.g. flattening test, bend test etc.

All pipes are then processed in finishing and testing area for pipe end preparation i.e. Facing/Beveling followed by hydrostatic pressure testing as per specification. Individual pipe is then visually inspected for the parameters specified in the specification before offering to the customer’s inspection, if any. Data of all tests is re-verified and submitted to the customers.